jtbartlett

Member

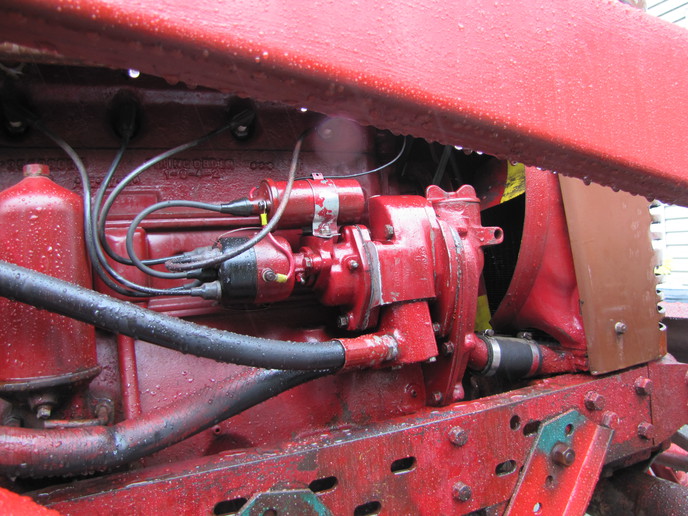

I have been working on a stage 2 super m adding a loader and Saginaw 3pt hitch. I have a 2 part problem that I cannot figure out. When engaging the hydraulic valve (resevoir under the tank) the engine seems to bog down much more than I think it should. The pump gets hot - again more than I think is right. It is pumping fluid because the loader, 4 cylinders and 3pt, 2 cylinders all extend and retract. That" problem #1. When I retract the loader arms I get hydraulic fluid blowing out of the fill cap along with a generous amount of air. I have been cycling the cylinders in and out hoping I was getting the air out of the lines however it has not stopped. I refill the resevoir as needed. Do I just keep doing this? All of my connections are tight and I"m not losing fluid anywhere else. Is it normal to have that much pressure through the return into the resevoir? I have 3 Gresen valves set up. They all seem to be OK but at this point anything could be wrong. Any ideas what my steps should be to track down these problems? Thanks.