I have recently purchased this tractor with the mounted loader on it. I would like to tear the tractor down to service it, and sandblast & re-paint it. First of all, I thought that by removing the front loader would be better than trying to paint it with it mounted on the tractor.

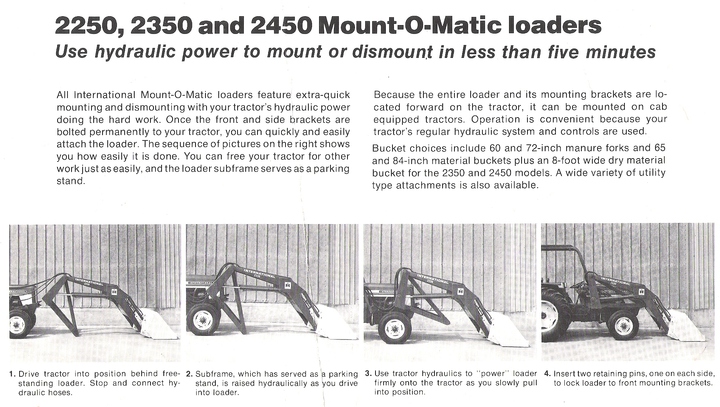

Would anyone happen to know how to remove it from the tractor? Is it a hard job? I have located (I think?) the 2 pins and the 2 quick connect hydraulic hoses that hold it on; BUT I would like to make sure before I mess something up. ALSO, I would like to know the correct process for removing and re-installing it that way it is an easy thing to do, and not a Pain-in-the-Rear. I am sure there is a "trick" to it.

I really look forward to the replies.

Thanks!!!!

Would anyone happen to know how to remove it from the tractor? Is it a hard job? I have located (I think?) the 2 pins and the 2 quick connect hydraulic hoses that hold it on; BUT I would like to make sure before I mess something up. ALSO, I would like to know the correct process for removing and re-installing it that way it is an easy thing to do, and not a Pain-in-the-Rear. I am sure there is a "trick" to it.

I really look forward to the replies.

Thanks!!!!