I don't want to hijack Cuttman's topic, But

Jim N said

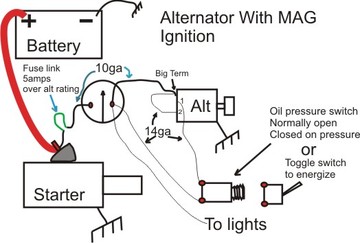

"An oil pressure switch that is open with no pressure, and closed when under pressure is ideal for this, as it is automatic (NAPA has them).

The wire with diode goes to this new switch ("T"ed into the oil pressure port.) and the switch is supplied with voltage from the starter switch on the hot terminal. A plain SPST toggle switch can be used in place of the oil pressure switch, but it must be turned on manually and off manually each time the tractor is operated."

I haven't been able to get it fixed in my mind how the engine could start if there was no current because the oil pressure switch had the current cut off.

Are you saying that the oil pressure switch is wired to energizing the starter , cranking the engine with the starter, temporarily providing that current until the engine starts and builds oil pressure??

Thanks,

TWheat

Jim N said

"An oil pressure switch that is open with no pressure, and closed when under pressure is ideal for this, as it is automatic (NAPA has them).

The wire with diode goes to this new switch ("T"ed into the oil pressure port.) and the switch is supplied with voltage from the starter switch on the hot terminal. A plain SPST toggle switch can be used in place of the oil pressure switch, but it must be turned on manually and off manually each time the tractor is operated."

I haven't been able to get it fixed in my mind how the engine could start if there was no current because the oil pressure switch had the current cut off.

Are you saying that the oil pressure switch is wired to energizing the starter , cranking the engine with the starter, temporarily providing that current until the engine starts and builds oil pressure??

Thanks,

TWheat