Okay, men, I'm stuck again. Please help.

'50 Cub engine has been rebuilt; new points, fire to plugs in order: 1-3-4-2.

Fire seems to be on exhaust stroke as fire is seen in manifold after I put fuel into any cylinder, install plug, then attempt to start.

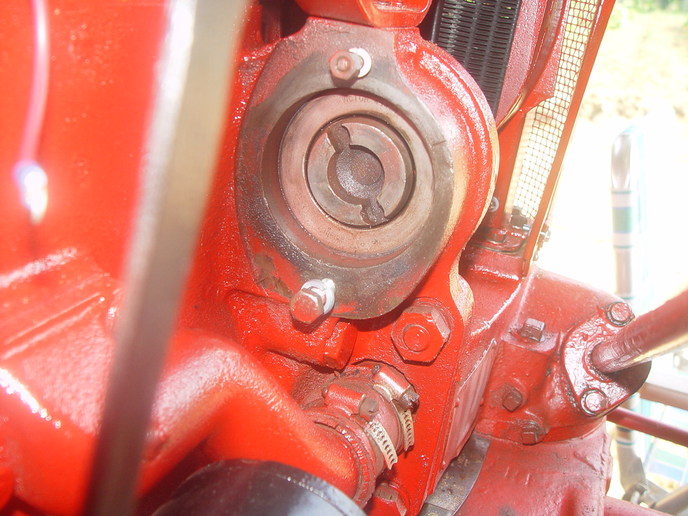

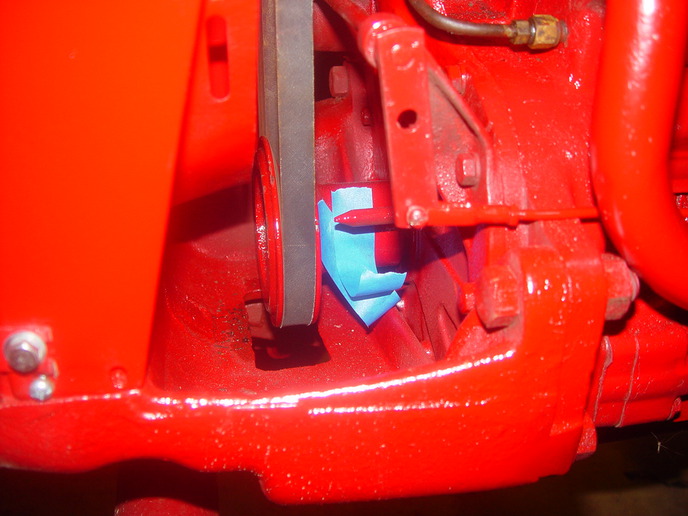

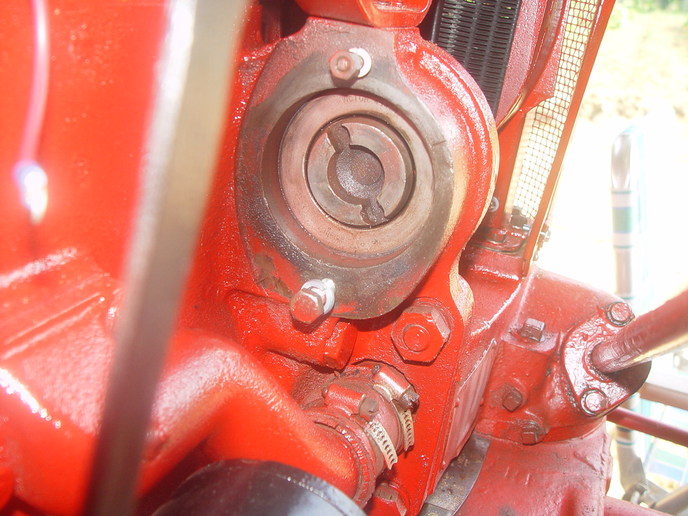

Hopefully a couple of photos are attached to help you set me straight. Thanks.

'50 Cub engine has been rebuilt; new points, fire to plugs in order: 1-3-4-2.

Fire seems to be on exhaust stroke as fire is seen in manifold after I put fuel into any cylinder, install plug, then attempt to start.

Hopefully a couple of photos are attached to help you set me straight. Thanks.