Seth Boyer

Member

It's been a few days since I've posted an update on my progress. Haven't got around to getting much more of the tractor tore down. My oldest son has just started his first season of T-ball so I've been spending most of my evenings out playing catch with him.

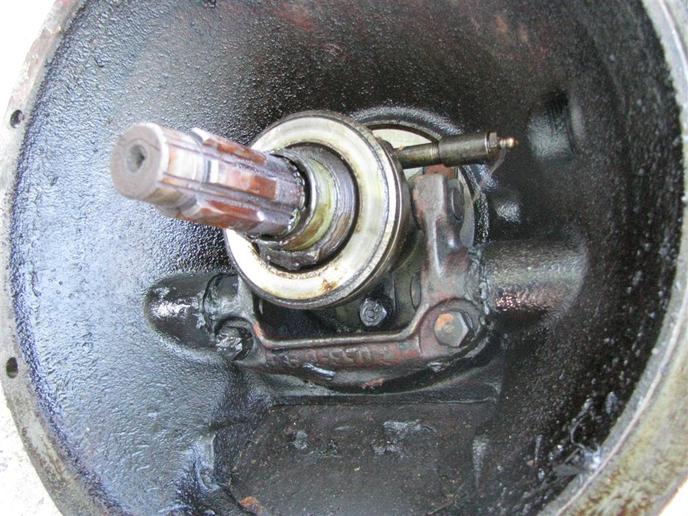

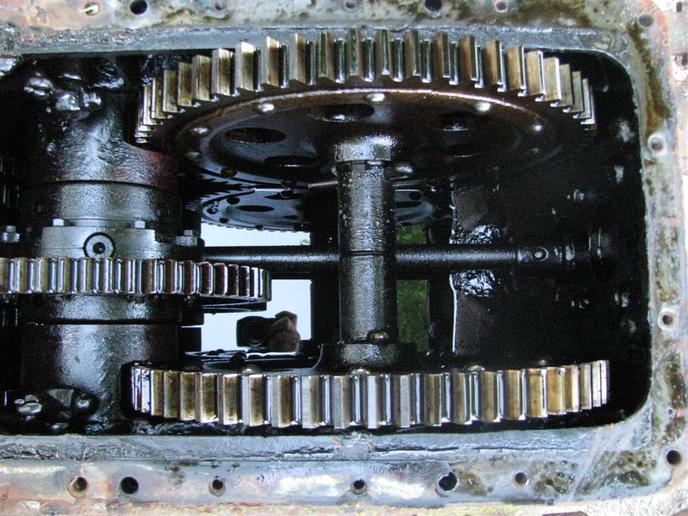

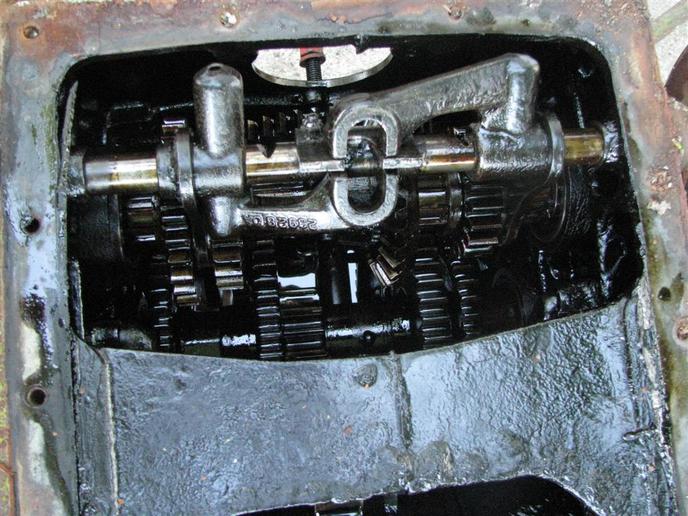

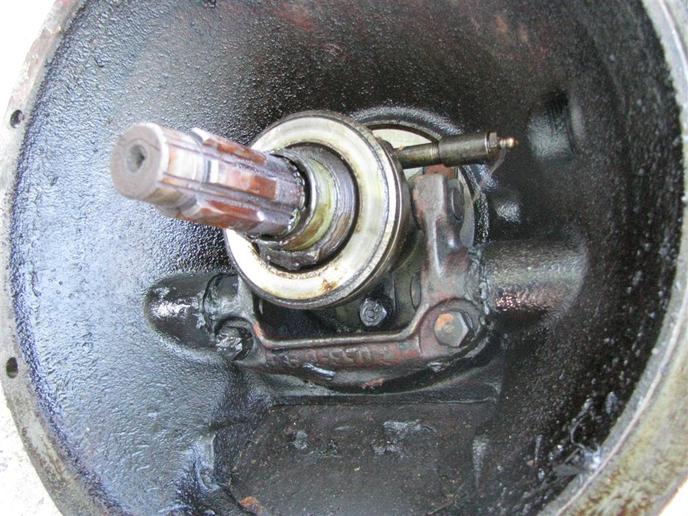

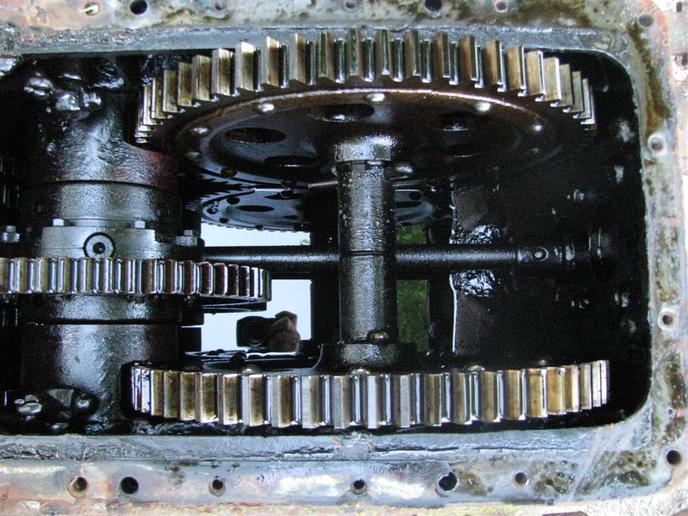

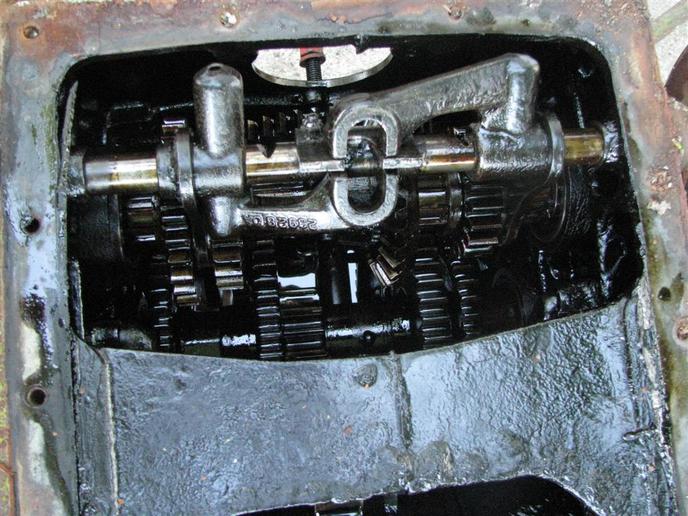

Tonight I got the tank supports taken off and removed the homemade belt pulley brake. I then removed the bell housing and transmission deck. I was happy to see plenty of oil in the tranny and no water! Clutch also seemed to be in great shape. All the gears are solid but I'm going to be getting my hands dirty cleaning everything up.

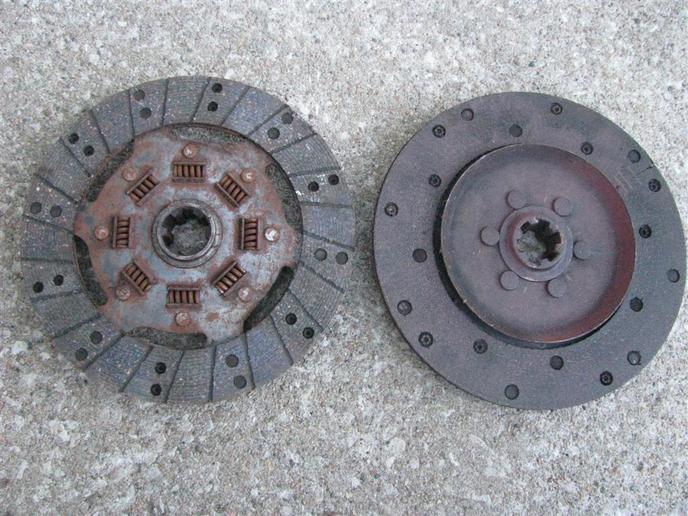

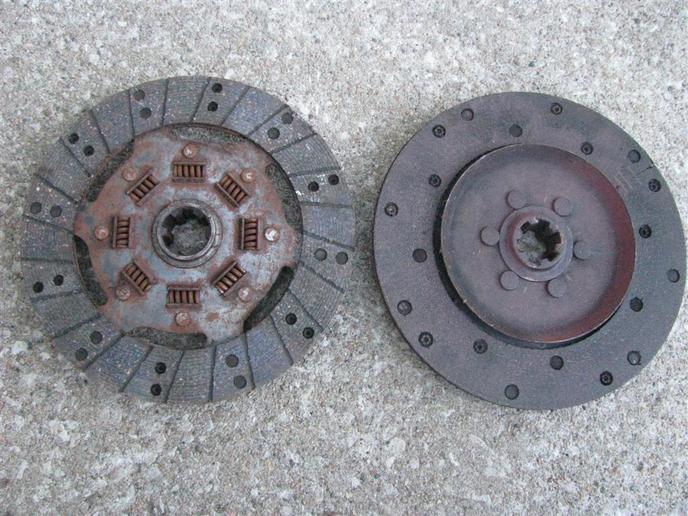

Of the two clutch plates the one on the left is what came off this tractor. The other one is off a later model F-14. Which of these two is better or considered more durable?

Tonight I got the tank supports taken off and removed the homemade belt pulley brake. I then removed the bell housing and transmission deck. I was happy to see plenty of oil in the tranny and no water! Clutch also seemed to be in great shape. All the gears are solid but I'm going to be getting my hands dirty cleaning everything up.

Of the two clutch plates the one on the left is what came off this tractor. The other one is off a later model F-14. Which of these two is better or considered more durable?