Tony_Idaho

Member

Hello,

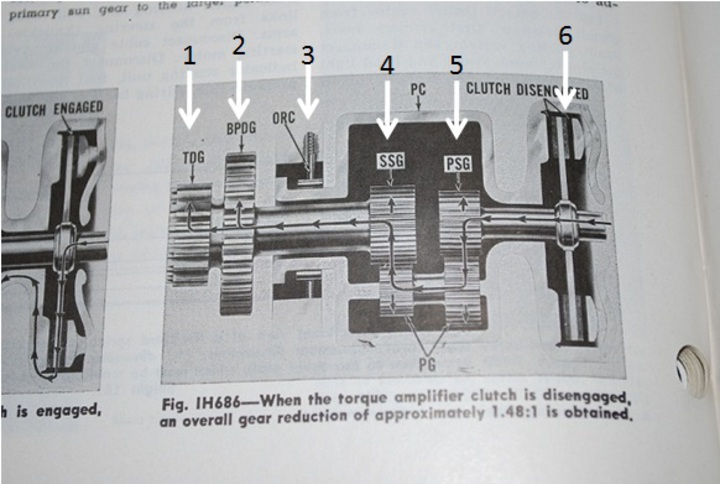

I was hoping someone could give me some suggestions on where the problem is with my Torque Amplifier. When I pull back the lever, I do get into the lower gear ratio as expected. But after a while sometime 1 minute sometimes 15 minutes, it comes out of gear. Meaning the tractor is still running, but wheels are not turning. If I move the lever back to the front of the tractor, the tractor starts moving again in the higher gear ratio. Then if I pull back to lever it again goes right into the lower gear ration and I have to repeat this over and over.

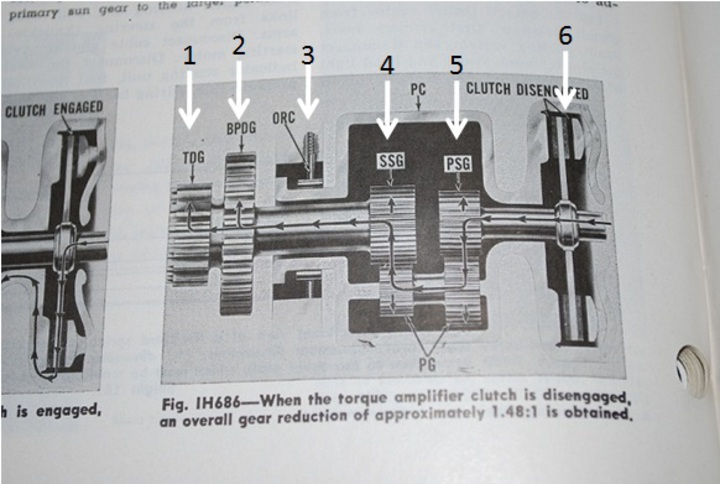

Can someone explain in the picture I am attaching where the issue might possibly be.

I have some numbers to help me out on which gears you might be talking about.

I was hoping someone could give me some suggestions on where the problem is with my Torque Amplifier. When I pull back the lever, I do get into the lower gear ratio as expected. But after a while sometime 1 minute sometimes 15 minutes, it comes out of gear. Meaning the tractor is still running, but wheels are not turning. If I move the lever back to the front of the tractor, the tractor starts moving again in the higher gear ratio. Then if I pull back to lever it again goes right into the lower gear ration and I have to repeat this over and over.

Can someone explain in the picture I am attaching where the issue might possibly be.

I have some numbers to help me out on which gears you might be talking about.