I recently purchased a Super C that is not charging. It will run for about a hour or so until the battery drains down and then dies. I pulled the alt off and gave it to my buddy to test and he said it's not charging, so he's going to either go through that one and rebuild it, or give me another GM 1 wire to put on in its place. My question is, all 12v tractors I've ever seen have a ballast resistor mounted near the distributor cap. This is my first 12v tractor and I know next to nothing about 12v conversions other than what I've seen. I wondered if not having one could have something to do with my charging problems. It has no resistor, a one wire hook up to the back of the alt, and the coil is a delco remy but I can't tell if it's a 12v or 6v coil, it's not marked. But the NEG side of the coil wire goes to the distributor.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Faster346

- Start date

I would just change out the coil to 12v internally resisted. As for the alternator, go with a Delco 10SI. Dont even bother with that Delco 12SI you have, thats a very early alternator that needs a regulator with it. You can pick up a 10SI re-man for around 50 bucks. Coil around 20 bucks.

Andrew

Andrew

Janicholson

Well-known Member

As crusty as that Alternator is, I would allow it to be melted down for the copper and aluminum.

I believe there are several answers to the question:

I would use a regular 10SI delco. Hook the #2 spade connector to the big terminal with a short wire and ring terminal.

Hook the #1 spade terminal to the ignition switch through a diode (3 amp 50 volt PIV) with the stripe on the diode toward the alternator.

(prevents the tractor from running after the key is shut off) A 15 ohm resistor will also work, as will a filiment style marker lamp bulb.

Each of these are simple to wire in.

The main terminal (big) goes to the amp meter on the side where the ignition and lights are hooked up.

Most one wire systems are "always on" thus there is always a draw on the battery, even when it is not running. The factory (GM) saw fit to wire it as above, So Do I.

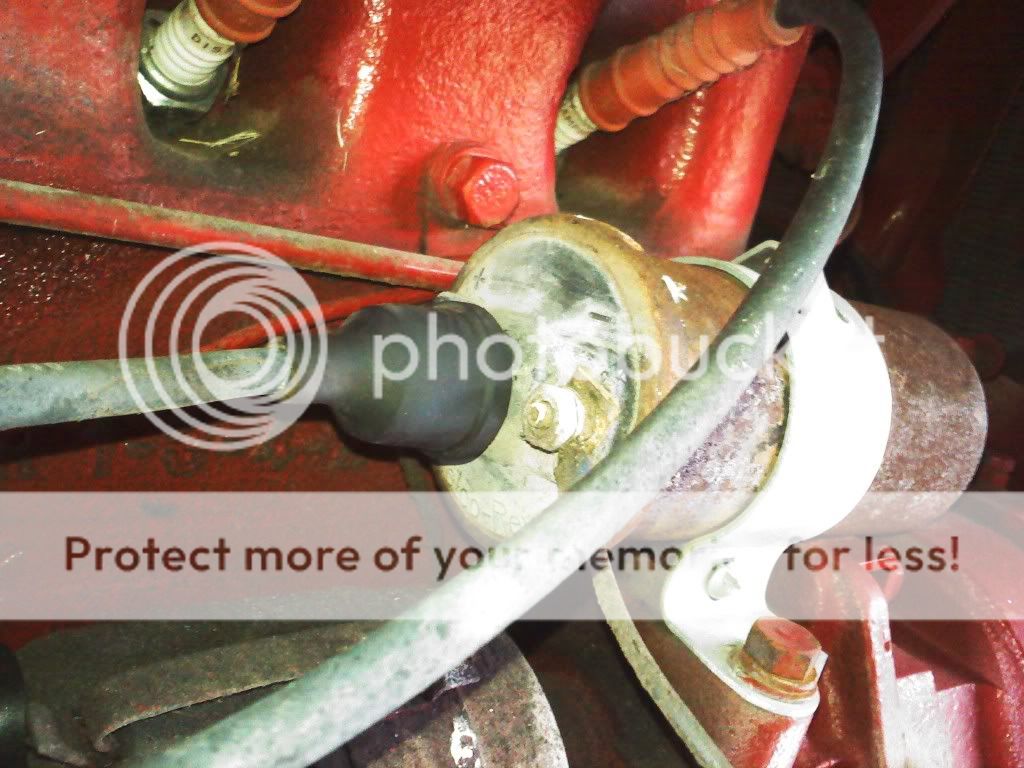

The coil shown probably needs a resistor to drop its input voltage. It looks like a mid 1960s GM coil that did use a resistor omn the fire wall. It is correctly wired as to polarity.

A 12volt no external resistor required coil can be used with no resistor.

A 6volt coil can be used with a resistor. Jim

I believe there are several answers to the question:

I would use a regular 10SI delco. Hook the #2 spade connector to the big terminal with a short wire and ring terminal.

Hook the #1 spade terminal to the ignition switch through a diode (3 amp 50 volt PIV) with the stripe on the diode toward the alternator.

(prevents the tractor from running after the key is shut off) A 15 ohm resistor will also work, as will a filiment style marker lamp bulb.

Each of these are simple to wire in.

The main terminal (big) goes to the amp meter on the side where the ignition and lights are hooked up.

Most one wire systems are "always on" thus there is always a draw on the battery, even when it is not running. The factory (GM) saw fit to wire it as above, So Do I.

The coil shown probably needs a resistor to drop its input voltage. It looks like a mid 1960s GM coil that did use a resistor omn the fire wall. It is correctly wired as to polarity.

A 12volt no external resistor required coil can be used with no resistor.

A 6volt coil can be used with a resistor. Jim

That alternator is an original delco-tron external mechanical regulaltor type. A 12 SI is near identical to a 10SI. It looks like some one has adapted a regulator right at the field terminals. Interesting. At any rate, I would follow advice of previous posters on alt. Far as coil, if you don't have an ohm meter, I am sure your friend who is checking alt has one, primary on a six volt coil will be less than 2 ohms and a l2 volt will be about 3 or 4 ohms. And no , it will not have any effect on the charging system, only ignition like short life of points if too much current flow or weak spark if not enough current flow through coil due to too much resistance.

(quoted from post at 12:35:11 02/01/11) Being lazy and cheap I have been running my 12 volt A for years without altenator or generator, just keep battery charged. My A will easily run 4 or 5 hours and still have pleny battery left for starting sounds like your battery is about gone.

Yeah, it will run for about a hour and then die. But I still want to fix the charging problem. I can't find a diagram anywhere for a one wire hookup, just the Delco 10si 3 wire setup. My buddy just rebuilt my alternator. We bench tested it and it put out 13.6 volts, so I'm hoping I can toss it back in and it will charge with the previous owners hacked up one wire no resistor setup. Then once it warms up a little I'm going to completely rewire it with new 10, 16, 4 GA wires, a new coil, and a 10si 3 wire.

Janicholson

Well-known Member

The resistor is needed now. The points and coil are both operating at 13.6 volts instead of 10 volts or what ever the non working system had in it. The resistor is going to be added anyway, so doing it now is just best practice. One of the reasons the system might be sputtering to a stop is an overheated coil (feel it just after it quits running and if it is toasty it may be causing your deteriorated performance.) Any mid 60s chevrolet ballast resistor, or chrysler resistor will work fine for just a few bucks.

Put it right on the coil bracket. Attach the ignition lead to it, and it to the positive coil terminal. Jim

Put it right on the coil bracket. Attach the ignition lead to it, and it to the positive coil terminal. Jim

(quoted from post at 14:28:37 02/01/11) The resistor is needed now. The points and coil are both operating at 13.6 volts instead of 10 volts or what ever the non working system had in it. The resistor is going to be added anyway, so doing it now is just best practice. One of the reasons the system might be sputtering to a stop is an overheated coil (feel it just after it quits running and if it is toasty it may be causing your deteriorated performance.) Any mid 60s chevrolet ballast resistor, or chrysler resistor will work fine for just a few bucks.

Put it right on the coil bracket. Attach the ignition lead to it, and it to the positive coil terminal. Jim

Okay, will do. I called NAPA and they have a ICR13 1.82 ohm ballast resistor for 11 bucks. Is that the one I want?

Okay, will do. I called NAPA and they have a ICR13 1.82 ohm ballast resistor for 11 bucks. Is that the one I want?

That'll do it. I've had one on my 140 for years.

Janicholson

Well-known Member

Yes with the ignition off, and the points open (or held open with a plastic knife or tab of cardboard). Set the MM on RX1 or Ohms Lowest setting. Jim

(quoted from post at 14:28:37 02/01/11) The resistor is needed now. The points and coil are both operating at 13.6 volts instead of 10 volts or what ever the non working system had in it. The resistor is going to be added anyway, so doing it now is just best practice. One of the reasons the system might be sputtering to a stop is an overheated coil (feel it just after it quits running and if it is toasty it may be causing your deteriorated performance.) Any mid 60s chevrolet ballast resistor, or chrysler resistor will work fine for just a few bucks.

Put it right on the coil bracket. Attach the ignition lead to it, and it to the positive coil terminal. Jim

I'm going to try to fire it up tomorrow and back it out of the trailer, and get it in the barn so I can put the ohm resistor in. I'll check to see if the coil gets warm before swapping it on, I'd feel better knowing that's the cause of it dying after running for a bit.

Janicholson

Well-known Member

If it does get warm, the coil is already damaged. I would suggest that even if it does continue to run with a ballast resistor, the coil is now suspect as it has heated to failure several times. Jim

(quoted from post at 08:32:59 02/02/11) If it does get warm, the coil is already damaged. I would suggest that even if it does continue to run with a ballast resistor, the coil is now suspect as it has heated to failure several times. Jim

If that does turn out to be the case, should I just take the ballast resistor back and put a 12v coil on it!?

For simplicity's sake, peace of mind, and preventative maintenance, just replace the coil with one marked "no external ballast resistor required" or similar now.

The coil only costs about $30, and they won't take the resistor back after you've used it. Some places are "no returns on electrical parts, period."

The coil only costs about $30, and they won't take the resistor back after you've used it. Some places are "no returns on electrical parts, period."

(quoted from post at 11:20:16 02/02/11) For simplicity's sake, peace of mind, and preventative maintenance, just replace the coil with one marked "no external ballast resistor required" or similar now.

The coil only costs about $30, and they won't take the resistor back after you've used it. Some places are "no returns on electrical parts, period."

I bought the resistor at Napa yesterday for like 11 bucks..for 19.88 they have a 12v coil they said would work. A IC14 12v coil. I think I'll just go that route as long as they take the resistor back. I haven't taken it out of the box yet.

OKAY! So, I went up to the farm this evening. I installed my new one wire alternator, and put on a Napa 12v coil without resistor. I think my battery is junk, it's dated 07, and barely turned over. So I got out the hand crank, never cranked a tractor in my life. After about 4 pulls on the crank it came to life, I backed it out of the trailer. The ammeter gauge didn't move off zero, I put my multimeter to the cables and my multimeter just went haywire reading -1.xx back and forth a lot.

I let it warm up for a few minutes, throttled it up about 3/4 and the ammeter gauge almost pegged at 20, then after about 2 mins came down to about the 10 mark, and then it randomly died after about 5 minutes of running. I cranked it back up, and it idled for about 10 more minutes until it got dark and I shut it off.

My question is, for whatever reason my multi meter wouldn't read the voltage in the battery while running, but isn't the needle being between 10-20 bad? I thought with 12v it would barely move? But I don't really understand how they work, so I figured I'd ask? Next step is to get a new 12v battery. I'm going to order a new 3 position switch, and re wire the tractor as soon as it's warm out. This wiring seems kind of sketchy, redoing it I believe I can handle. I just don't have a 100% grasp on how the charging system operates, though I feel I know how everything hooks up after studying diagrams.

I let it warm up for a few minutes, throttled it up about 3/4 and the ammeter gauge almost pegged at 20, then after about 2 mins came down to about the 10 mark, and then it randomly died after about 5 minutes of running. I cranked it back up, and it idled for about 10 more minutes until it got dark and I shut it off.

My question is, for whatever reason my multi meter wouldn't read the voltage in the battery while running, but isn't the needle being between 10-20 bad? I thought with 12v it would barely move? But I don't really understand how they work, so I figured I'd ask? Next step is to get a new 12v battery. I'm going to order a new 3 position switch, and re wire the tractor as soon as it's warm out. This wiring seems kind of sketchy, redoing it I believe I can handle. I just don't have a 100% grasp on how the charging system operates, though I feel I know how everything hooks up after studying diagrams.

Janicholson

Well-known Member

Digital MM take voltage samples at some 100 times per second and put those numbers on the screen. A farmall has such noise in the system that it reads garbage.

An expensive Fluke meter can average these and eliminate noise. An analog meter (with a needle and meter face works perfectly. Jim

An expensive Fluke meter can average these and eliminate noise. An analog meter (with a needle and meter face works perfectly. Jim

(quoted from post at 08:23:47 02/03/11) Digital MM take voltage samples at some 100 times per second and put those numbers on the screen. A farmall has such noise in the system that it reads garbage.

An expensive Fluke meter can average these and eliminate noise. An analog meter (with a needle and meter face works perfectly. Jim

I believe my alt guy has an analog meter. I will give that a try. I appreciate all the help, Jim.

Janicholson

Well-known Member

You are welcome, the old brutes are more complex than the average person ever imagined. Old technology was very different as well. Jim

Similar threads

- Replies

- 9

- Views

- 436

- Replies

- 11

- Views

- 894

- Replies

- 17

- Views

- 588

- Replies

- 9

- Views

- 963

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy