charles todd

Well-known Member

I have a Farmall 504 with one set of weights on the rear. I have another set awaiting installation and possibly a third in the future. I have a loader and one set plus fluid is sometimes not enough. I also work it pretty good on a varity of projects and the extra weight will help.

I have heard to mount the first TWO sets on the same bolts then use the "C" shaped holes. I have the split type weights. Do they go on the same way or alternate 90 degrees out? I do not plan to buy more bolts to mount them two deep and the 3/4" x 5" bolts currently on there will only engage one deep.

What size (5/8" or 3/4") bolts do I use to mount from the "lips"? Do I use washers? I know square heads were OEM, but will GR 8 hex heads work? Also what lenght? I have seen 6 sets of full (1 piece) weights held on with just two pieces of ready rod per side. Thats a lot of weight (6 x 150) for the cast wheel on two holes. It was at a tractor pull on a stock Farmall 450. They may have been temporary.

Here are the pics of my weights and the orientation on the tractor.

Current setup:

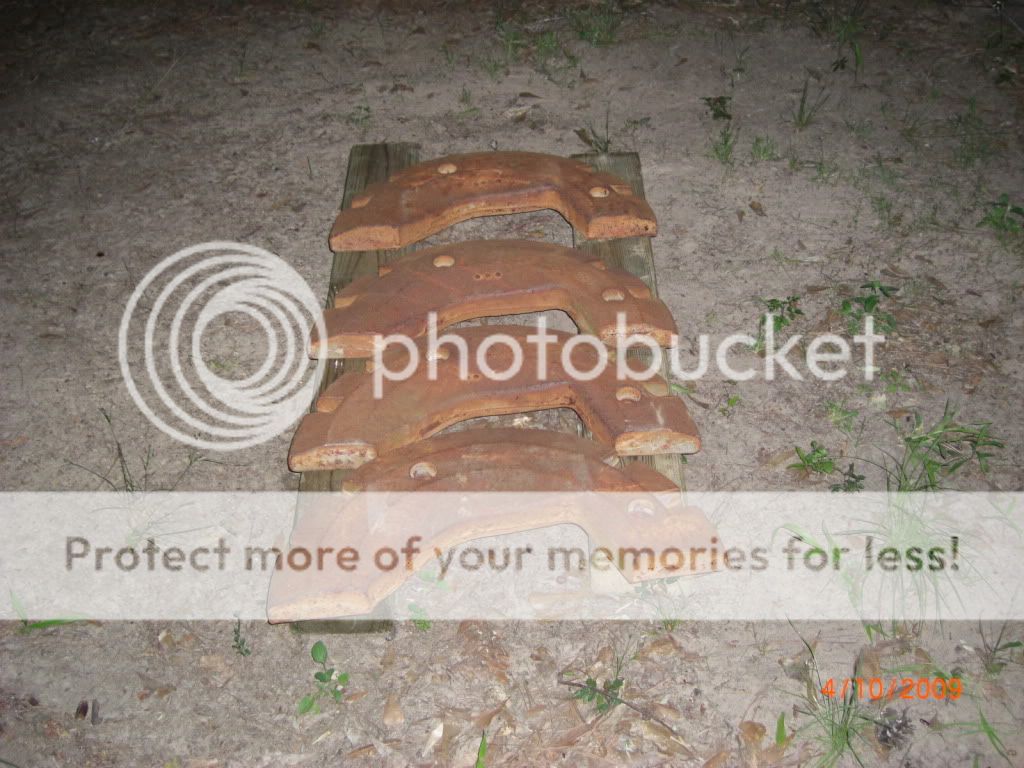

2nd Set:

Thanks guys,

CT

I have heard to mount the first TWO sets on the same bolts then use the "C" shaped holes. I have the split type weights. Do they go on the same way or alternate 90 degrees out? I do not plan to buy more bolts to mount them two deep and the 3/4" x 5" bolts currently on there will only engage one deep.

What size (5/8" or 3/4") bolts do I use to mount from the "lips"? Do I use washers? I know square heads were OEM, but will GR 8 hex heads work? Also what lenght? I have seen 6 sets of full (1 piece) weights held on with just two pieces of ready rod per side. Thats a lot of weight (6 x 150) for the cast wheel on two holes. It was at a tractor pull on a stock Farmall 450. They may have been temporary.

Here are the pics of my weights and the orientation on the tractor.

Current setup:

2nd Set:

Thanks guys,

CT