Since I have had the 674, I have been annoyed by the way one of the lines for the steering cylinder hung below the axle. I had some free time this evening so I was going to build a little skid plate to protect it. After working on the plate and just about calling it done, I took another look at the line I was trying to protect. This is when I realized that it would fit correctly if I turned the fitting on the end of the rod. I did this and all looked good. I decided to go ahead and have another line made because the old one wasn't looking too hot. Since I had the tractor outside the barn, I put the line back on, and prepared to move it into the barn where I could leave it out of the weather while I was having line made tomorrow. It starts up, and everything works normal. I turn the steering wheel lock to lock twice and POW. Epic fail pow. The rod end broke off right where it screws into the clevis. I managed to take it all off and remove the broken rod piece from the clevis before unhooking the mower that was on the back (all 1400lbs or so) and winching the tractor into the barn so I could work on it out of the rain tomorrow evening.

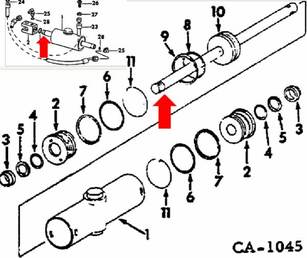

Obviously I'm going to need either a new rod/packing/etc or a new cylinder. The question is: What made it break? The only thing I can think of is that I took the play out of where the rod screws into the clevis. This happened when I was turning the fitting. I did loosen the jam nut on the fitting to turn it, but I didn't really think anything of the 1/8-1/4 turn I put on the rod. I assume that the rod is supposed to be backed off a certain amount from the bottom of the clevis. Is that right? If that is the case, what is the magic number? I'd hate to put this back together and experience this chain of events again.

Thanks all.

Obviously I'm going to need either a new rod/packing/etc or a new cylinder. The question is: What made it break? The only thing I can think of is that I took the play out of where the rod screws into the clevis. This happened when I was turning the fitting. I did loosen the jam nut on the fitting to turn it, but I didn't really think anything of the 1/8-1/4 turn I put on the rod. I assume that the rod is supposed to be backed off a certain amount from the bottom of the clevis. Is that right? If that is the case, what is the magic number? I'd hate to put this back together and experience this chain of events again.

Thanks all.