charles todd

Well-known Member

This has got to be the best thing for a Farmall or IH since Red paint! I had called about two months ago to order the 56033 kit (fits 340, 460, 504, 544, 560, 606, 656, 660, 664, 666, 686). Last week they finally had a new batch in. Allied Precision is the only company I know of that builds these kits, I have looked far and wide. They also build parts for tractor pulling such as clutches and gears. They build HD Dodge clutches as well as have parts for IH, John Deere, Case, Allis Chalmers, Massey Ferguson, Oliver, White, Minneapolis Moline, and Ford tractors. Pretty slick company.

Their website is, http://www.allied-precision.com/index.htm

Now for the juicy stuff... Pictures of my journey with the Farmall 504 conversion. The reason I wanted the filter extension was that I replaced the old 12 GPM pump with a fresh 17 GPM after installing a Koyker FEL... I had a lot of pump noise after the 17 GPM was installed. I thought the rubber lines were transmitting the sound... More flow, though sometimes the hydraulics were jerky...

There will be many pics here.

Modified Hydraulic Lines

Old Hydraulic Filter Unit

Whats This??? Could this be part of the FLOW PROBLEM?

Seems the Bigger 17 GPM Sucked the Guts out of the Filter Gasket!

Here is the Gasket after I Removed the Filter.

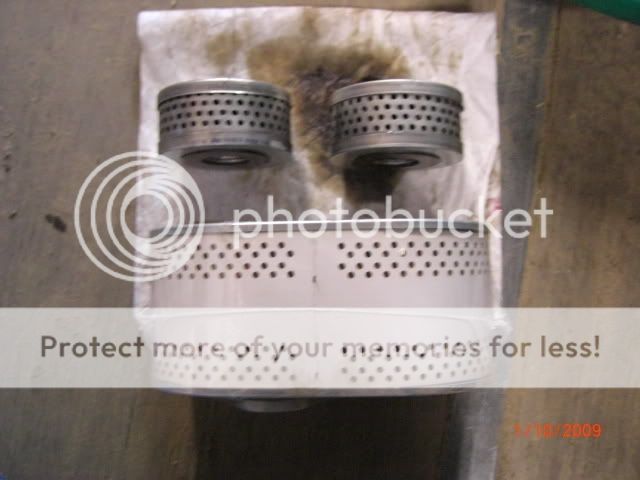

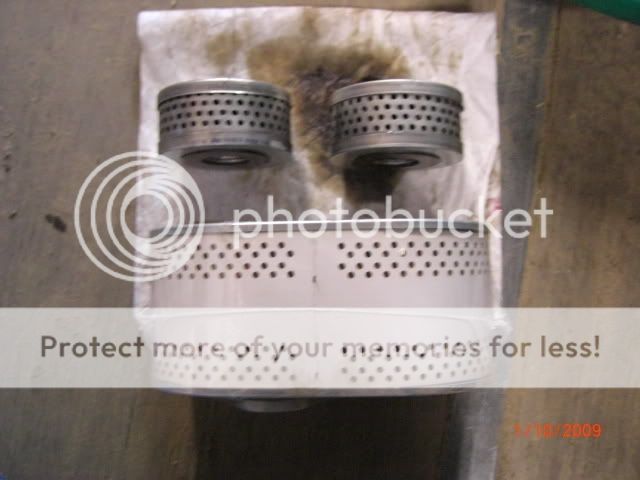

Size Comparison Between the Two...

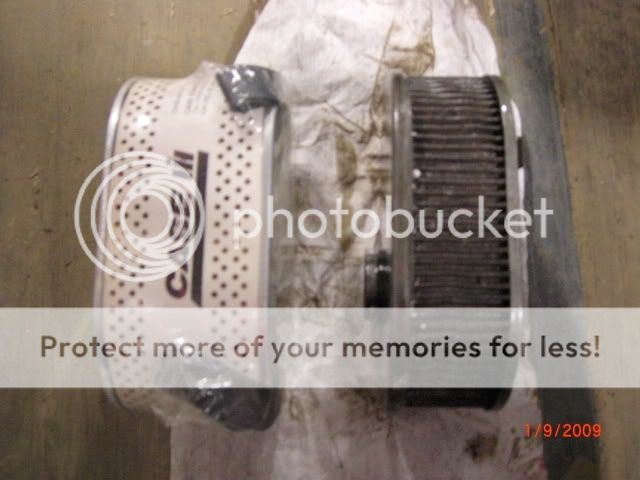

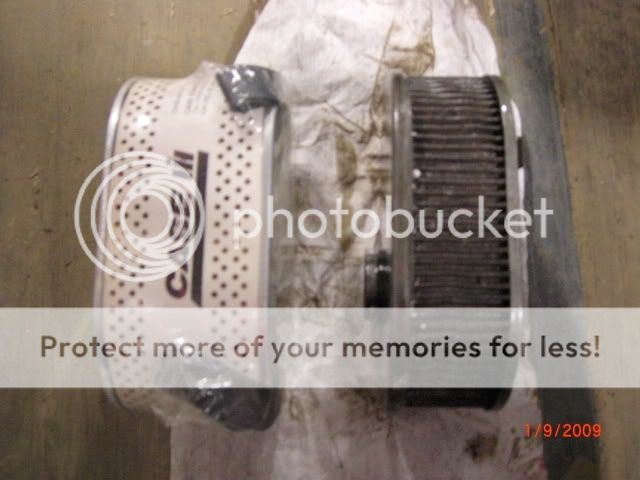

Now for the Actual Element Comparison...

Just a Little Difference in Surface Area in Square Inches

Shot of the Extension... I Usually Repaint Anything I Remove... One Piece at a Time, Like Johnny Cash.

Thanks for reading this, I appoligize for the many pictures for those on dial-up, but I am really excited about this filter upgrade . It was about 45 degrees today when I cranked er' up and it only had a little whine for about 5 minutes, then went away as the oil heated a little. I feel I was starving the pump drastically with the old filters and the sucked out gasket.

. It was about 45 degrees today when I cranked er' up and it only had a little whine for about 5 minutes, then went away as the oil heated a little. I feel I was starving the pump drastically with the old filters and the sucked out gasket.

I fully recommend this to any one owning an IH product or the select few JD's that the also make extensions for. I believe it is worth its weight in, well not gold but maybe silver

Charles

Their website is, http://www.allied-precision.com/index.htm

Now for the juicy stuff... Pictures of my journey with the Farmall 504 conversion. The reason I wanted the filter extension was that I replaced the old 12 GPM pump with a fresh 17 GPM after installing a Koyker FEL... I had a lot of pump noise after the 17 GPM was installed. I thought the rubber lines were transmitting the sound... More flow, though sometimes the hydraulics were jerky...

There will be many pics here.

Modified Hydraulic Lines

Old Hydraulic Filter Unit

Whats This??? Could this be part of the FLOW PROBLEM?

Seems the Bigger 17 GPM Sucked the Guts out of the Filter Gasket!

Here is the Gasket after I Removed the Filter.

Size Comparison Between the Two...

Now for the Actual Element Comparison...

Just a Little Difference in Surface Area in Square Inches

Shot of the Extension... I Usually Repaint Anything I Remove... One Piece at a Time, Like Johnny Cash.

Thanks for reading this, I appoligize for the many pictures for those on dial-up, but I am really excited about this filter upgrade

I fully recommend this to any one owning an IH product or the select few JD's that the also make extensions for. I believe it is worth its weight in, well not gold but maybe silver

Charles