Chad,

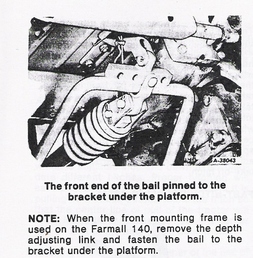

Here is a scan out of my 140 Operators manual showing the bail pinned under the platform like Hugh was talking about.

I was thinking too if you had to make that curved piece you might make it a little bigger and just drill a half inch hole in the end and bolt the depth adjusting link to it instead of the platform. That way you wouldnt have to remove anything. Wonder what Hugh thinks of that idea?

Here is a scan out of my 140 Operators manual showing the bail pinned under the platform like Hugh was talking about.

I was thinking too if you had to make that curved piece you might make it a little bigger and just drill a half inch hole in the end and bolt the depth adjusting link to it instead of the platform. That way you wouldnt have to remove anything. Wonder what Hugh thinks of that idea?