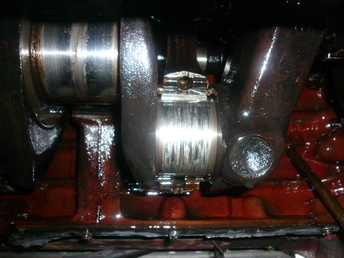

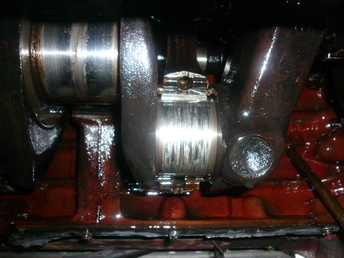

Removed the rod caps off of pistons 2 and 3. Piston 2 is the one that got hot and it appears that and feels like the crank journal has been scored, although not terribly bad. None of the bearings wear “spun” and the rod bearing for piston 2 was also scored, but the others were fine. The thrust bearing on the main journal has been shredded apart as seen in the picture.

So how bad do these look to everyone? I am tempted to just put in a new rod bearing on piston 2 and possibly a new main bearing. Maybe I could just run 40 weight oil! Who thinks that’s a good idea?

So how bad do these look to everyone? I am tempted to just put in a new rod bearing on piston 2 and possibly a new main bearing. Maybe I could just run 40 weight oil! Who thinks that’s a good idea?