charles todd

Well-known Member

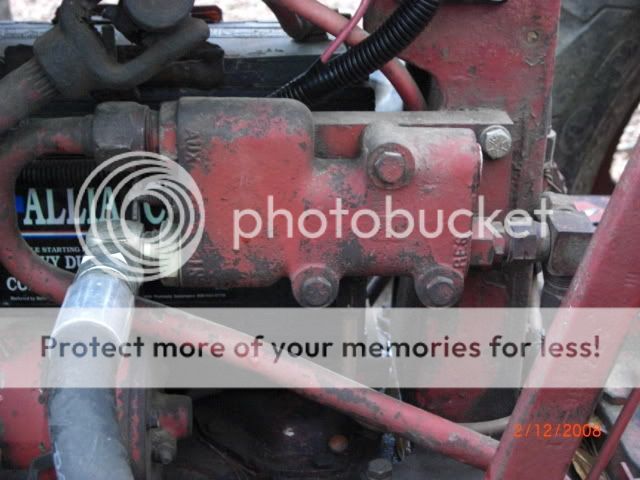

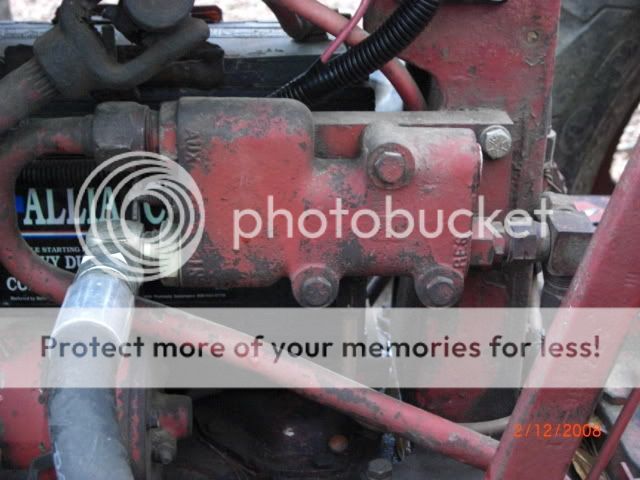

First lets look at the unit in question: The Power Steering Flow Divider Valve.

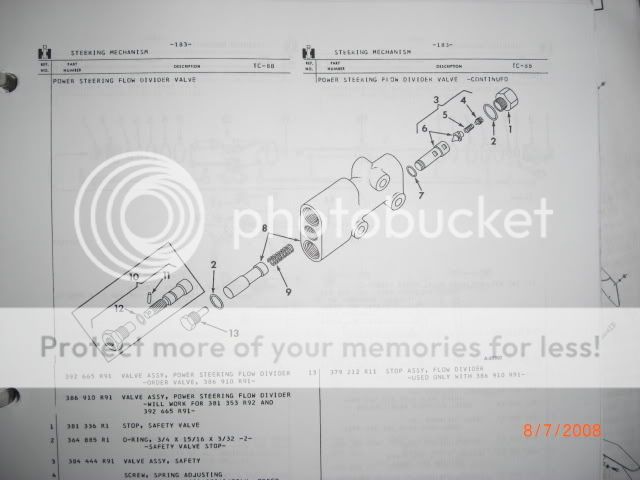

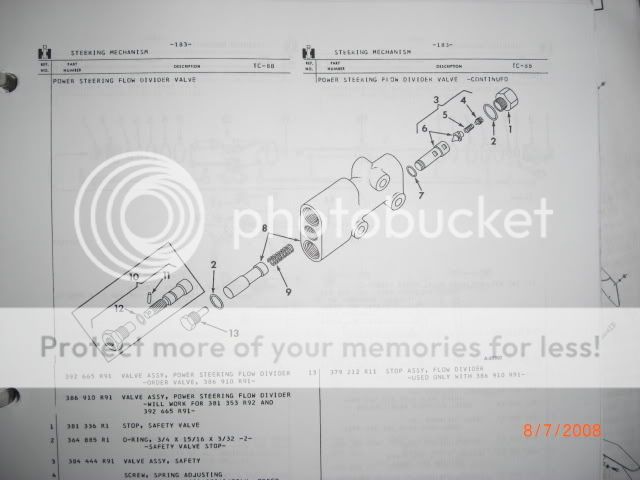

This is on a Farmall 504 Diesel with remotes and power steering (obviously because it has this). Here is the breakdown from the TC-88 parts manual.

This is what I've got; low remote hydraulic pressure to or from the valves.

I have replaced the pump with a NEW 17GPM unit (previously 12 GPM), NEW oil, NEW filters (stock 12 GPM filters, two small round units), REBUILT remote valves, NEW male and female couplings, and REBUILT 1600 psi hydraulic pilot relief valve (looked good, little wear).

I still have the same problem. When I stroke the valve to put down pressue on the loader to raise the front end off the ground the power steering flow divider squeals. Also I can feel heat from the pilot relief valve during this time. It did this with the 12 GPM pump, just the loader moved slower, not it is ugly fast. I do not think it is a filter issue either.

Is the relief too weak? Is the power steering flow divider bypassing? Is the remote valve bypassing (probably not)?

I know that using the rear remotes for loader service is usually looked down on. I am searching for a 3 spool valve with float, power beyond, and an adjustable pressure regulator. I will plumb this before the remotes to give the loader 2000-2500 psi.

Thanks in advance,

Charles

This is on a Farmall 504 Diesel with remotes and power steering (obviously because it has this). Here is the breakdown from the TC-88 parts manual.

This is what I've got; low remote hydraulic pressure to or from the valves.

I have replaced the pump with a NEW 17GPM unit (previously 12 GPM), NEW oil, NEW filters (stock 12 GPM filters, two small round units), REBUILT remote valves, NEW male and female couplings, and REBUILT 1600 psi hydraulic pilot relief valve (looked good, little wear).

I still have the same problem. When I stroke the valve to put down pressue on the loader to raise the front end off the ground the power steering flow divider squeals. Also I can feel heat from the pilot relief valve during this time. It did this with the 12 GPM pump, just the loader moved slower, not it is ugly fast. I do not think it is a filter issue either.

Is the relief too weak? Is the power steering flow divider bypassing? Is the remote valve bypassing (probably not)?

I know that using the rear remotes for loader service is usually looked down on. I am searching for a 3 spool valve with float, power beyond, and an adjustable pressure regulator. I will plumb this before the remotes to give the loader 2000-2500 psi.

Thanks in advance,

Charles