farmallcody

New User

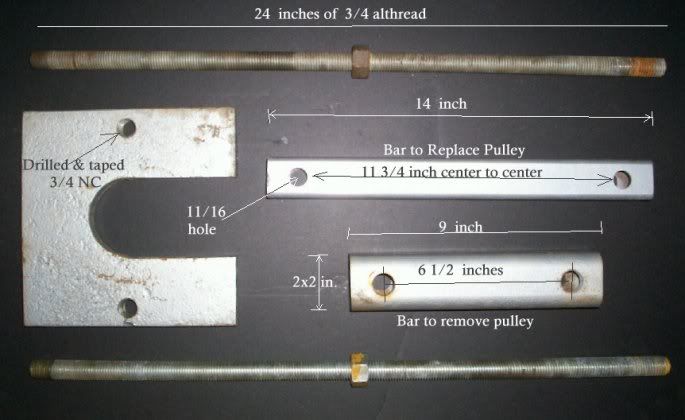

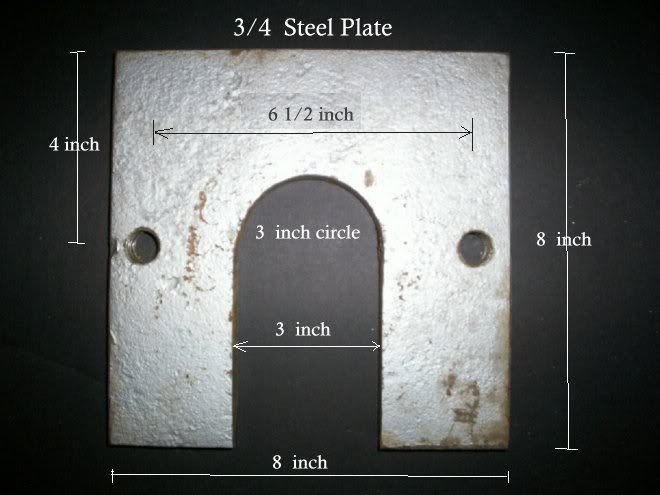

I need to take off the crankshaft pulley

I already tried a gear puller as well as heating it up a little

the gear puller only broke the crankshaft pulley and know i need to replace it

any ideas on how to get it off and where to buy a new one

It needs to come of before my father gets home any ideas :?:

-------------------------------------------------------------------------------------

why farm some when you can farmall

just keep the tire in the furrow and you will be fine

I already tried a gear puller as well as heating it up a little

the gear puller only broke the crankshaft pulley and know i need to replace it

any ideas on how to get it off and where to buy a new one

It needs to come of before my father gets home any ideas :?:

-------------------------------------------------------------------------------------

why farm some when you can farmall

just keep the tire in the furrow and you will be fine