Ive plowed since the late 50s on HILLY and rolling ground. All dad had was narrow fronts. Ive never seen one to tip, and only heard of 1. Youd have to see the slope he was plowing to understand how it could happen. I can put one front in/over the furrow and with the L brake keep it there during a left turn in the furrow. Ive NEVER had one crack my knuckles, but I got my L thumb discombulated on an F-20 when I got to the end of the furrow and turned short, and the cable brakes took over. I like the short turnin that a narrow front gives at the end of the row. If your plowing where you might turn over, YOU GOT NO BUSINESS PLOWING THERE

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Farmallb

- Start date

Yeah, and that 1 that tipped probably would've gone over even with a wide front, because wide fronts do not help with stability AT ALL. They pivot in the center. By the time the front end hits the stop where it could stabilize the machine, you're already past the point of no return, and you're going over.

It's a myth. It's an old wives' tale. Wide fronts are not more stable. They ride better because in most cases, only one wheel hits the pothole instead of both wheels. They make it easier to see where the wheels are pointed.

You also have to remember that a lot of the people running these machines now are not old hands that grew up on them in the 40's and '50s. It's the next generation who grew up on more modern tractors that take a lot less skill to operate. After about 1963 you didn't need to know how to set up a tractor and plow because the tractor was so heavy and powerful you could just point and go.

It's a myth. It's an old wives' tale. Wide fronts are not more stable. They ride better because in most cases, only one wheel hits the pothole instead of both wheels. They make it easier to see where the wheels are pointed.

You also have to remember that a lot of the people running these machines now are not old hands that grew up on them in the 40's and '50s. It's the next generation who grew up on more modern tractors that take a lot less skill to operate. After about 1963 you didn't need to know how to set up a tractor and plow because the tractor was so heavy and powerful you could just point and go.

I too was raised on narrow fronts and we also had wide fronts. I prefer the narrow front, but they are not being sold now because they are less stable. This is a fact. I be an Ag-engineer and the tipping radius for a tricycle is shorter making it more likely to tip. IH quit making the B's back in the 40's because of tipping problems. We have been talking about the relative safety of the two front end types and the difference it makes in operation and comfort. Unless you are willing to suspend reason you must accept the fact that the narrow front requires a greater degree of care in operation to remain safe, that is to ramain amoung the living. All equipment requires skill and care in operation. One of my high school classmates almost cut off his foot within the last few months operating a push lawn mower. He had been doing it since he was a kid and it happened when he was almost 60.

You are correct however to say that it falls to the operator to be safe. Yes it took a good deal of skill to operate the older tractors, and a lot more energy to work hand lifts, but do not doubt that the modern operator could run those units if he had to. Our dads were highly skilled with mules and horses. I doubt many of us have skills in that area but we could do it if we had to (if we could come up with the energy)!! Just think, when we got off the row when cultivating, we plowed up two or four rows. These modern guys (if they were to actually cultivate) would plow up 12---16 or even more rows. I can still hear my dad yelling at me to "quit plowing up my corn"!! And tobacco, forget it we simply did not even consider getting off the row there, hence the popularity of the one row cultivision A series. These modern operators just need dad's yelling and they would be as skilled as any.

As far as busted knuckles and broken hands, it was the wide Fords that were dangerous. Hit a stump, fence post, or furrow just wrong with a Ford and the wheel could become a weapon (My uncle broke his hand that way). I never saw a narrow front do that.

You are correct however to say that it falls to the operator to be safe. Yes it took a good deal of skill to operate the older tractors, and a lot more energy to work hand lifts, but do not doubt that the modern operator could run those units if he had to. Our dads were highly skilled with mules and horses. I doubt many of us have skills in that area but we could do it if we had to (if we could come up with the energy)!! Just think, when we got off the row when cultivating, we plowed up two or four rows. These modern guys (if they were to actually cultivate) would plow up 12---16 or even more rows. I can still hear my dad yelling at me to "quit plowing up my corn"!! And tobacco, forget it we simply did not even consider getting off the row there, hence the popularity of the one row cultivision A series. These modern operators just need dad's yelling and they would be as skilled as any.

As far as busted knuckles and broken hands, it was the wide Fords that were dangerous. Hit a stump, fence post, or furrow just wrong with a Ford and the wheel could become a weapon (My uncle broke his hand that way). I never saw a narrow front do that.

(quoted from post at 08:28:42 03/24/09) I be an Ag-engineer and the tipping radius for a tricycle is shorter making it more likely to tip. .

Never trust an AG-E that talks like a pirate. :wink:

The wide front, as noted before, has to pivot, so that actually leaves a bit wider footprint with the narrow front; one could make arguements about the height of the fulcrum, but this all has to be right at the point where the rearend desires tipping anyway. However, that all changes if turning at all sharp; also in rocky soil, hitting a rock with the higher front wheel of a NF is a guarantee to go over - if already right at the point of tipping. Then the visibility of the wheels does leave some skill questions; the irony [or maybe death knell; if the position of the wheels in narrow rows wasn't enough nowdays] is also all the neat advantages that made narrow popular for 20 years do take a bit of skill. True too, a wide front may signal a rock that could hit the high rear tire, while a narrow front sneaks by it.

Finally the center of gravity is a big player, those RowCrop tractors regardless of brand were made for clearance and visibility, but this doesn't help a center of gravity good for hugging hills.

As far as keeping the front end down, that's a different issue that you'd need to be pulling awful hard to bring into the equation and other than getting too light to steer or bouncing ect, I really don't see as part of stability at that.

Never drove those Fords much, but around here the Regulars [with open "sector rack/pinion" steering gears; the F-20s and a few similar configurations in other brands too were cursed to a lesser extent] were known as the knuckle busters - I was always taught to keep thumbs outside both on the crank and the steering wheel: between them I'd run out of fingers to count on one hand the times I appreciated that advice if I hadn't followed it.

Dave H (MI)

Well-known Member

I'm sorry, don't know what an Ag-engineer is, but I think you are just plain wrong. Three points on the ground is more stable than four. Take your camera tripod and a table with four legs out into your field and see which one sits stable most consistently. There was a study done years ago, and I wish I still had the link, at one of the major midwest universities on this topic and the tricycle tractor won out by a slight margin. I found this link when I was first looking to buy a tractor. At the time I was pretty worried about moving to a tricycle from the wide fronts I was used to. Experience taught me that this worry was unfounded and that both are safe tractors if used safely. As for the Farmall B? If stability were the reason for it's discontinuance then I think they would have immediately dropped narrow fronts on the other tractors in the line. Of all the narrows, the B sits lowest and has the widest stance for it's size and weight. After many hours and multiple uses, I consider this model to be one of the safest...once again, if used safely. IMHO

ScottyHOMeY

Well-known Member

I can agree with your presumption on the geometry of what happens when the center of gravity falls outside the footprint on any tractor, but I'd challenge (over a beer and in a friendly fashion!) the assertion about the B being discontinued because of tipping problems. I dont know that the Bs or even the BNs had any kind of reputation for being tippy and, even if they did, I can't imagine that IH tried to"fix" that by replacing it with the C (many, many of which were built with narrow fronts), which centers its weight even higher with only and extra 6" of wheel width?? Leaving the 100" axle option out, the tipping geometry is only worse, but still not inherently unsafe.

I'd argue that the A (or the Cub or any offset tractor) even with it's wide front was inherently "tippier", especially to the left side, than any narrow front where the center of gravity is basically along the centerline of the tractor. Even with the advantage of the extra weight of the longer diff shaft and housing on the right, the As were commonly sold with a stamped steel wheel on the left and the heavier cast wheel on the right, just to move the center of gravity away from that narrow left side. If tipping were the driving issue, they'd have abandoned the As, not the Bs.

My view is that they kept the A as their small, truck farming tractor. For the C, they simply regeared (including the big rubber gears on the 36" rims) to build tractor with the same motor as the B that would pull a heavier load. The other good reason for them to have kept the A is that they were selling scads of them for mowing roads and ditches, being that the short left side didn't hang out into the travel lane as much.

That's my 2 cents.

I'd argue that the A (or the Cub or any offset tractor) even with it's wide front was inherently "tippier", especially to the left side, than any narrow front where the center of gravity is basically along the centerline of the tractor. Even with the advantage of the extra weight of the longer diff shaft and housing on the right, the As were commonly sold with a stamped steel wheel on the left and the heavier cast wheel on the right, just to move the center of gravity away from that narrow left side. If tipping were the driving issue, they'd have abandoned the As, not the Bs.

My view is that they kept the A as their small, truck farming tractor. For the C, they simply regeared (including the big rubber gears on the 36" rims) to build tractor with the same motor as the B that would pull a heavier load. The other good reason for them to have kept the A is that they were selling scads of them for mowing roads and ditches, being that the short left side didn't hang out into the travel lane as much.

That's my 2 cents.

HENRY E NC

Member

Being raised on an A and an H and M(both tricycle) I can assure you that the a is as likely to go over as soon as the H or M,I have had the good fortune to have gone thru a tipover on the A. Went to the left side going too fast and hitting a rock that spun the wheel. Of course I was only 12 YO at the time but scared the bejesus out of me as I went flying. At 77 I still have an A and an M and prefer the narrow front end. I have also had a wide MF wide front end and darn near flipped that with a loader on and one tire went down in the mud and I barely got it under control. Course I was 65 then. Henry

Janicholson

Well-known Member

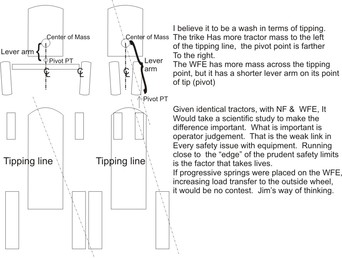

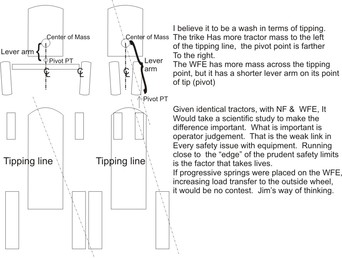

A bit of a diagram.

Boy, it would be nice to be so busy I would not have to deal with this. I don't drink beer but I would love to do it over a good plate of fried fish or something like that.

The problem with the B was the small wheels. More weight was needed at the axel ends to reduce tipping moment. The C and the B were almost the same height at the motor (both are about 28" at the front bolster). The B gives the illusion of being lower, but it is not. So the C was made with larger wheels that could carry more ballast. The C is heaver but the extra weight is either the rear wheels or is placed between the rear wheels. More weight at the axel ends reduces tipping moment. Other than being totally impractical for cultivating (the offside row was out of sight), the B's were more dangerous than the H, M, or the F series previously made. Check the records. The Cub and the A have special ballast built into the wheels to reduce tipping moment.

I can't argue with emotion, but I can argue math. The tipping radius for a tricycle front is approximately half the radius for a wide front. Draw a line from the contact point for the front wheel to the contact point for the rear wheel. Measure the distance from the center of the tractor (center of gravity) to the line at the midpoint between wheels and you will have the approximate tipping radius. It will not be exact because the engineer will have to determine the location of the center of mass to make the measurement and also consider such things as second moment. Suffice it to say the tipping radius is reduced by the shape of the footprint and will be approximately half for a tricycle front. For first moment the shorter the tipping radius, the more likely the unit is to tip over and it is an inverse linear relationship. When motion is introduced and second moment has to be considered, tipping moment increases inversely with the square of the tipping radius. Remember the three wheelers Honda and Yahama made. Gone! Why are they gone? Because of instability (and subsequent law suits). The equipment manufactures would still be offering narrow fronts if they knew they were as safe as wide fronts. I do not know for sure, but I would bet the fronts were altered so that the old boasters could not be moved over to the newer models (for fear of lawsuits). If the manufacturers could they would still be selling narrow fronts just because guys like us like them so much! They can't because of this litigious society we live in.

Come on down and bring the fish. I might even furnish you a beer! Larry Mc

The problem with the B was the small wheels. More weight was needed at the axel ends to reduce tipping moment. The C and the B were almost the same height at the motor (both are about 28" at the front bolster). The B gives the illusion of being lower, but it is not. So the C was made with larger wheels that could carry more ballast. The C is heaver but the extra weight is either the rear wheels or is placed between the rear wheels. More weight at the axel ends reduces tipping moment. Other than being totally impractical for cultivating (the offside row was out of sight), the B's were more dangerous than the H, M, or the F series previously made. Check the records. The Cub and the A have special ballast built into the wheels to reduce tipping moment.

I can't argue with emotion, but I can argue math. The tipping radius for a tricycle front is approximately half the radius for a wide front. Draw a line from the contact point for the front wheel to the contact point for the rear wheel. Measure the distance from the center of the tractor (center of gravity) to the line at the midpoint between wheels and you will have the approximate tipping radius. It will not be exact because the engineer will have to determine the location of the center of mass to make the measurement and also consider such things as second moment. Suffice it to say the tipping radius is reduced by the shape of the footprint and will be approximately half for a tricycle front. For first moment the shorter the tipping radius, the more likely the unit is to tip over and it is an inverse linear relationship. When motion is introduced and second moment has to be considered, tipping moment increases inversely with the square of the tipping radius. Remember the three wheelers Honda and Yahama made. Gone! Why are they gone? Because of instability (and subsequent law suits). The equipment manufactures would still be offering narrow fronts if they knew they were as safe as wide fronts. I do not know for sure, but I would bet the fronts were altered so that the old boasters could not be moved over to the newer models (for fear of lawsuits). If the manufacturers could they would still be selling narrow fronts just because guys like us like them so much! They can't because of this litigious society we live in.

Come on down and bring the fish. I might even furnish you a beer! Larry Mc

Hugh MacKay

Well-known Member

L Mack: Those must have been awful stupid folks that could upset a B, must have been over a cliff. I garentee you an A or SA set at 44" wheel tread will upset much quicker than a B. Flipping over backwards would be much different.

It really doesn't matter which model you have, safety is all about ballast and lowering the center of graviety. If that is right, I'll chalange you to a run off, you pick tour model in wide front, I'll pick the same model in narrow front and I'll follow you anywhere you wish to drive.

It really doesn't matter which model you have, safety is all about ballast and lowering the center of graviety. If that is right, I'll chalange you to a run off, you pick tour model in wide front, I'll pick the same model in narrow front and I'll follow you anywhere you wish to drive.

Yep Hugh. The B is one of the harder ones to turn over. I have seen just as many wide fronts rolled over as tricycles. Been mowing steep hills all my life with SC's and M's and never turned one over yet. My FIL mowed with an old B and took it places you would have sworn it would have slid off of.

I mow lots of places here that most folks won't mow with any kind of tractor.

I mow lots of places here that most folks won't mow with any kind of tractor.

ScottyHOMeY

Well-known Member

LOL! Fish sounds good, with hot biscuits and coffee! I sense a smelt feed comin' on in the near future.

I agree that the B and C are essentially the same height. I just put the nose gear from a BN under what had been my wide-front Super C. But the center of gravity on the C/SC is a good bit higher than on the B. As and Bs alike, you had the mass of the final drives much closer to the ground moving the COG lower. On the C/SC, you have a much heavier transmission, diff and their housing behind that same axis as the center of the crank, and similar weight and length in the axle housings to the diff shaft housings of the B/BN. By moving the concentration of the mass up from the drop-drives to the same axis as the crank, you have raised the COG, and it will move to the tipping line much more quickly.

As for using the span of the front wheels to determine that line, I'd say that holds true within the range of the axial motion of the front pivot on a wide front when the weight is being carrtied to both wheels, but once that limit is reached, you lose your rectangle and are back to the triangle of a narrow front, and the apex at the front of the tractor moves to either the pivot point, or to any stops further out the radius, moving the tipping line to that point on the low side and much closer to the wheel, and transmitting the bulk of the weight on the front to that wheel. Jim N's drawing below, I'm still scratching my head, but he hits the point I'm trying to make. He draws the tipping line for a wide front to the center pivot point. Not sure if that's the true case or not, but even if it is, the wheels at the end of a wide front serve as outriggers.

So all of that was factored into the engineering of the chassis, and works on fairly regular ground even on a reasonable side slope and up to the point where you encounter the limit on the pivot point. But that's where operator judgment enters back into it.

I've rambled on enough. (How many times has this horse been whipped to death on these boards, but I still enjoy the discussion!)

Bottom line, yes, with all other factors the same, a wide front is geometrically more stable than a narrow front. But the finer point is that that does not make a narrow front inherently unstable and, I would argue further, that the offset of an A, or the shifting of the COG when a wide front hits the limits of the front pivot, pose just as much hazard and require just as much care in their operation as a narrow front. They can go over just as quickly as a NF which has a COG that is centered and does not move.

Now, I need to run to the store and see if I can still get fresh smelts. It's gettin' close to the end of the season, if it isn't already over.

I agree that the B and C are essentially the same height. I just put the nose gear from a BN under what had been my wide-front Super C. But the center of gravity on the C/SC is a good bit higher than on the B. As and Bs alike, you had the mass of the final drives much closer to the ground moving the COG lower. On the C/SC, you have a much heavier transmission, diff and their housing behind that same axis as the center of the crank, and similar weight and length in the axle housings to the diff shaft housings of the B/BN. By moving the concentration of the mass up from the drop-drives to the same axis as the crank, you have raised the COG, and it will move to the tipping line much more quickly.

As for using the span of the front wheels to determine that line, I'd say that holds true within the range of the axial motion of the front pivot on a wide front when the weight is being carrtied to both wheels, but once that limit is reached, you lose your rectangle and are back to the triangle of a narrow front, and the apex at the front of the tractor moves to either the pivot point, or to any stops further out the radius, moving the tipping line to that point on the low side and much closer to the wheel, and transmitting the bulk of the weight on the front to that wheel. Jim N's drawing below, I'm still scratching my head, but he hits the point I'm trying to make. He draws the tipping line for a wide front to the center pivot point. Not sure if that's the true case or not, but even if it is, the wheels at the end of a wide front serve as outriggers.

So all of that was factored into the engineering of the chassis, and works on fairly regular ground even on a reasonable side slope and up to the point where you encounter the limit on the pivot point. But that's where operator judgment enters back into it.

I've rambled on enough. (How many times has this horse been whipped to death on these boards, but I still enjoy the discussion!)

Bottom line, yes, with all other factors the same, a wide front is geometrically more stable than a narrow front. But the finer point is that that does not make a narrow front inherently unstable and, I would argue further, that the offset of an A, or the shifting of the COG when a wide front hits the limits of the front pivot, pose just as much hazard and require just as much care in their operation as a narrow front. They can go over just as quickly as a NF which has a COG that is centered and does not move.

Now, I need to run to the store and see if I can still get fresh smelts. It's gettin' close to the end of the season, if it isn't already over.

I can't talk about plowing, but I have been mowing (both belly and pull-behind) with a 140 on hilly ground for 43 years. I don't think you can tip a 140 on grass with left side high; it will slide down first. Left side up, I will mow as steep as I can stay on. If you mow right side high on steep ground, you deserve to end up wearing your tractor.

ScottyHOMeY

Well-known Member

Yep, one of my points exactly. That offset can be deadly, even with the weight of a mower and a cast wheel on the right. They'll lean a lot farther to the right than they will to the left and still stay on all fours.

I do not know any math past long division but if you were close by I would challenge you to a game of tip over chicken if you would give me a 2/1 advantage for my narrow front. I worked for 37 years as R&D technician with dozens of mechanical engineers, some rather sharp, some rather dull and any worth their salt did not rely to much on their calculations without real world tests. Narrow fronts were factory available at least until late seventys on tractors as large as 986 but almost no one bought them so they were discontinued due to lack of demand.

As a point of argument, before the wide front hits the stop when tipping, the tipping line is a triangle just like others have said. Once it hits the stop, the resistance point moves out to the width of the front tire. The fact that the unit has started tipping before the stop has been reached has to be considered in calculating tipping. As many have pointed out, that tendency to roll on the front axel axis tends to instability, but it is necessary for operation on uneven ground. A crawler has no front axel rotation and can be rather rough to operate on uneven ground and a corner is often suspended in mid air. A tractor with no front axel rotation would be the same.

The weight of the tire, hub, axel, and wheel weight is significantly more for the C than the B. The final drives for the B are fixed at about 30 inches from the center of the unit. A smaller tire weighs less, the wheel weights are about the same but the hubs for the B are not as heavy as for the C. This additional weight at the end of the axel more than compensates for the heaver chassis of the C. Much of this additional chassis weight was placed low to reduce tipping.

The weight of the tire, hub, axel, and wheel weight is significantly more for the C than the B. The final drives for the B are fixed at about 30 inches from the center of the unit. A smaller tire weighs less, the wheel weights are about the same but the hubs for the B are not as heavy as for the C. This additional weight at the end of the axel more than compensates for the heaver chassis of the C. Much of this additional chassis weight was placed low to reduce tipping.

Anonymous-0

Well-known Member

I would think for the most part we could argue the question and never get anywhere with it. If it's going to tip and you really feel unsafe there than why be there. I beleve many MEN will say that they will go anywhere with there tractor and many do but for the sake of safety why? I do some 4 wheeling and get into steep places and the best advice I know when there is the thought of rolling over is to turn toward into the roll. On the narrow 300 I have I would say to heck with the equipment behind me and turn. Better to repair the equipment and use it another day than to have a Farmall 300 hood ornament of my own on my chest. I guess I say to each his own but remember that you can be safe alot but dumb once. I think if your use your equipment and you know just how it will act you will have a greater sence of how it will handle your work.

Now that's my two cents.

Now that's my two cents.

A lot of people have been seriously injured or lost their lives in tractor roll over accidents. Doubtful that any accident victim thought his tractor wasn't stable enough for the terrain they were on. Tractor roll overs are why they have roll bars and seat belts now. Unless you're using both, best stay away from any questionable side hill. Just not worth the risk.

Hugh MacKay

Well-known Member

Farmallb: These discussions about narrow front versus wide front as usual are quite useless. These old tractors had relatively light chassis compared to new tractors of the same hp. If they were not balasted correctly, they were all quite dangerous narrow or wide front.

Couple that with the fact most large tractors had wheel tread set on 72" centers for 36" rows, some even wider. Narrow front did not disappear for safety reasons, but rather consumer demand. That consumer damand changed due to herbicides and less row crop cultivation. The combine also put the mounted corn picker out of commission. Another factor was improved wide fronts that didn't require an acre to turn. Probably the three biggest reasons narrow front disappeared.

Couple that with the fact most large tractors had wheel tread set on 72" centers for 36" rows, some even wider. Narrow front did not disappear for safety reasons, but rather consumer demand. That consumer damand changed due to herbicides and less row crop cultivation. The combine also put the mounted corn picker out of commission. Another factor was improved wide fronts that didn't require an acre to turn. Probably the three biggest reasons narrow front disappeared.

Similar threads

- Replies

- 15

- Views

- 2K

- Replies

- 1

- Views

- 646

- Replies

- 14

- Views

- 3K

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy