By Anthony West Any restorer who has some knowledge of turn of the century farm machinery, will recognize the name Lanz Bulldog!! This machine was to say the least unusual in its appearance. The huge flywheel and coffee percolator shaped exhaust. Along with square body lines and cylinder head protruding forward of the front axle. Would become the visual differentiation that people would quote to separate the Lanz from other period machines. The Marshall company based at the Briannia Works in Gainsborough England, were at that period of time Britains leading Boiler makers. The company itself was based on the improve and exploit policy as opposed to being single product orientated. That is to say that they would very often acquire industrial machines of all sorts and improve them... then re-market them. They also sub contracted to their competition, making boilers and casting machinery parts in their own foundries.

In order to beat the economic recession ( and probably not to be beaten!!) Marshalls acquired both Models of the available Lanz machine which arrived at the Britannia works and were dismantled!! in a preamble to the new venture. From the very outset it was the Marshall Co., intention to improve on the design of the Lanz. The Marshall concept however was to be a full diesel machine. Whilst surface ignition engines would run on almost anything one could lay one's hands on!! the Marshall would require a supply of fuel oil, but although this was initially thought to be a drawback to the design. Diesel at 6d per gallon would ultimately prove its major advantage. By 1930 the first Marshall machine was attending agricultural shows and was tagged as the 15 / 30 model E. A single cylinder engine of 8" bore by 10.5" stroke, running at 550 rpm, using crankcase compression at a compression ratio of 15:5/8:1, formed the forward part of the frame with the gearbox and axle housing to the rear. Unlike many of its contemporaries which required a hot bulb for starting and running, ( and we all know how arduous that can be by hand!!) the 15 / 30 was started using ignition papers placed in a holder which protruded from the combustion chamber. Another useful feature was the fitting of the radiator in the normal transverse position, the fan being driven by skew gears. Three forward and one reverse gears were provided, and the whole thing weighed in at 70000lbs. The 15 / 30 was to prove to be a competitive machine. It wasn't without its faults though, the weak points most noticed were the clutch release mechanism gear selector and leather seals....not forgetting the injector system. Initially the 15's were constructed in line with company tradition. That is to say that each machine was as individual as the customer so no two were alike. If the customer wanted red white and blue wheels...then thats what he got!! As nice as that may seem there are hardly any records appertaining to these early machines so information is at best sketchy!! After a period of time the world saw the release of a revised model tagged the 18 / 30. Noticeable changes were that the square appearance was dropped, thinner steel was used to save weight and reduce cost. The rear transmission housings were strengthened and the fuel problem was resolved by the use of the Bosch unit and injector. The 18 / 30 was at best heavy!! it was a cumbersome 3.5 tons and was too heavy really for many jobs where direct haulage or implements were involved, As a stationary power unit though it was undisputed. By 1934 the British built Fordson was readily available, at only £155, as opposed to £310 for the Marshall. The Marshall team had to come up with a suitable alternative to meet the market and thus the 12 / 20 was born. The 12 / 20 had been modified so that the engine was now a 6.5/8" bore by 9" stroke a design that was to prove so popular and reliable it would continue on for the next 22 years unchanged. Pneumatic tires as opposed to steels and cleats were now also available to cater for popular demand. The 12 /20 continued production for the next 4 years and was then renamed the "M". This saw further refinements to the gearbox and engine castings, the M was in reality at the limit of the power output for a single cylinder engine, if failings in the structure were not to be incurred through stresses. However the single cylinder was so popular that post war attempts were made to take the same engine, to 50 Hp, in an attempt to compete with multi cylinder machines. Towards the end of the war decisions had to be taken as to what shape the diesel tractor would take in the future. Following a new marketing policy within the Marshall company each product group had a name e.g., Road Marshall for road making equipment. Thus Field Marshall was adopted for the wheeled tractor range. The new "high powered" British diesel tractor the Field Marshall, Series 1 was announced. It was in appearance a more modern machine than the M but this cosmetic treatment was only in line with current rends to hide the working parts with styled sheet metal.

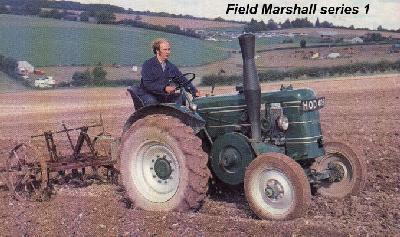

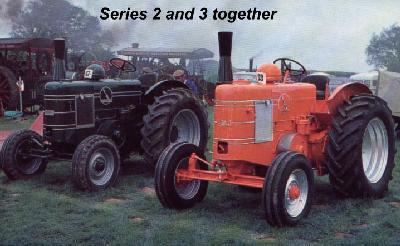

The model M is basically a Lanz Bulldog in all but name, the livery is as standard fern green with red cast wheels or steels, the front is very square and the exhaust best described as a squat pressure cooker shape. the Series one, is easily discerned by the snub nose of the front and lack of the bulbous air cleaner on the bonnet. It also has the later taller coffee percolator exhaust. Early Series 1's shared M wheel centers, whilst the later ones had pressed steel centers and flat half shaft ends. The Series 2 whilst being the same fern green was turned out with pressed steel wheels which were silver in color. The addition of the bulbous air cleaner to the top of the bonnet is another differentiating feature. The Series 3 was altogether a taller machine and even if in fern green paint it cannot be mistaken for the 1& 2. This machine was turned out in bright orange and silver livery and this machine had a more pronounced hopping effect when on tick over.

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today. Copyright © 1997-2024 Yesterday's Tractor Co. All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters |